Südseite des Gebäudes Bismarckstraße / © HsH/IKME

Südseite des Gebäudes Bismarckstraße / © HsH/IKME Westliches Ende des Gebäudes Bismarckstraße / © HsH/IKME

Westliches Ende des Gebäudes Bismarckstraße / © HsH/IKME

Energy management for buildings

Combined heat and power plants (CHP) are compact units for efficient and low-emission energy supply. They are suitable for use in a wide variety of areas. For example, CHP units have already found their way into the supply market of residential buildings a few years ago, and in the future can additionally support the energy supply in electric vehicles.

The efficient operation of a CHP unit requires the use of a suitable energy management, which orientates the control of the CHP unit and its ancillary components in the overall supply system to the energy demand. The challenge here is the simultaneous need-based production of electricity and heat, as the consumption in buildings is subject to strong variations, both seasonal and daily. In addition, the thermal and electrical consumption in most cases match neither in terms of amount nor in terms of time (Fig. 1).

CHP units available on the market are typically heat-led when used in single- and multi-family homes, i.e. switch-on time and duration depend on the heat demand in the building.The parallel-generated electricity remains in the house; excess electrical energy is fed into the public grid.

Although the CHP unit can be operated more evenly and therefore more gently in this mode of operation due to the small fluctuations in the heat demand, the power production often takes place outside the peak load periods, so that the use of own power and consequently the cost-effectiveness of the CHP unit are limited.

Conversely, aligning the energy production at the electrical load leads to frequent switching on and off of the CHP unit and thus to increased wear of the system. Moreover, this mode of operation involves the risk that, especially in the warm season, a high proportion of thermal power is generated, which cannot be consumed. This in turn contradicts the idea of an efficient energy supply. In order to fully exploit the potential of a CHP unit, it is therefore necessary to lead the operation of the plant to the economic benefit for the customer instead of just following one load value.

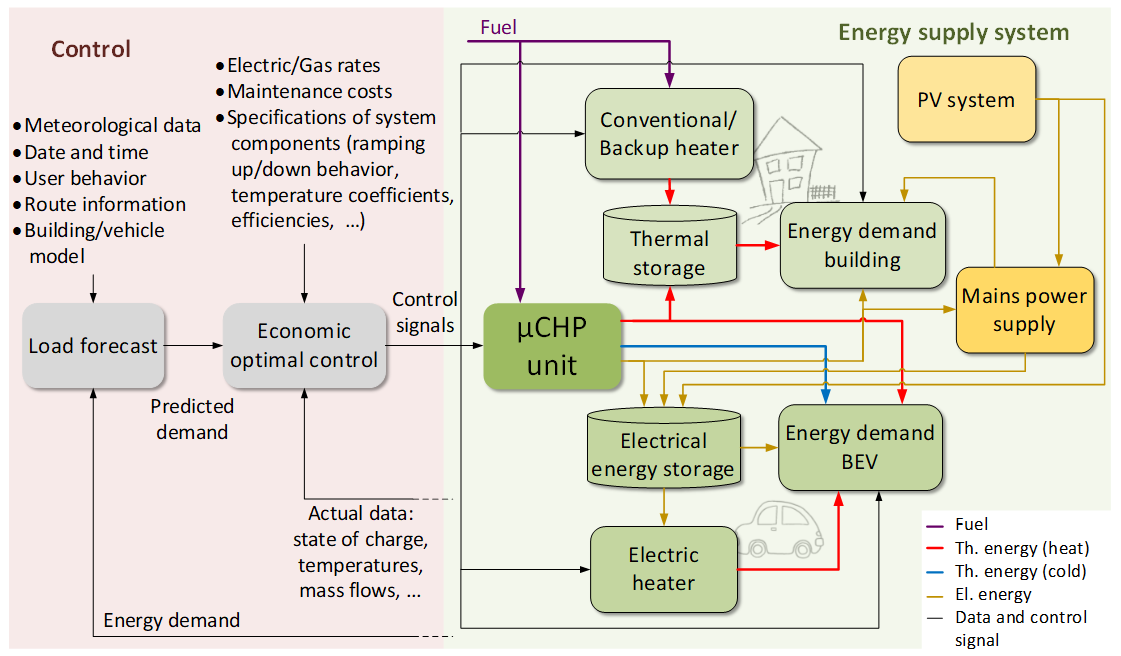

The aim of this project is the development of an appropriate energy management, which leads to a minimization of the operating costs. The planned control strategy essentially comprises two components: a model predictive control and a load forecast (Fig. 2). The control is based on a model of the energy supply system and has as input variables, among others, the energy and maintenance costs as well as a predicted load curve. Depending on these input data, control variables for the individual energy generators and other control devices are calculated, which lead to a coverage of the electrical and thermal requirements in the supply object and at the same time minimize the overall costs.

Load prediction follows a hybrid approach that combines a physical building or vehicle model with a model based on historical consumption data (machine learning). In order to further increase the forecast accuracy, also relevant, i.e. the energy consumption affecting information such as weather data, user behavior and route information are considered.

Contact

Dimitri Bitner, M.Sc.

Prof. Dr.-Ing. Martin Grotjahn